SANDING

研磨について

Expanding sanding technique

- About the 2nd century, I was rubbing things with dried shark shell. In the 13th century, in China, there was a record that used seashells fixed with parchment with rubbery sap, and it is said that in Switzerland glass powder was used on parchment or leather for a while after being used. Since then, people have sought "better things", have made various tools, and have been improving materials and making methods. Time flows, the shells develop into artificial abrasives, rubber resin liquids to glue and resin, parchment to paper, cloth, varieties and shapes also diversify, abrasive cloth paper is used as a major sanding and polishing tool, each industry It is responsible for one part. And today's sanding technique continues to change at a very fast speed. At RIKEN CORUNDUM, we are also challenging fields such as shot blasting, polishing and wafer cutting using abrasive grain itself as it is. In addition, we are also developing business in office automation equipment fields such as grip rollers (such as printer feed rollers) that applied and developed coating technology for abrasive cloth paper. RIKEN CORUNDUM will continue to strive to develop products that satisfy customers and create new value.

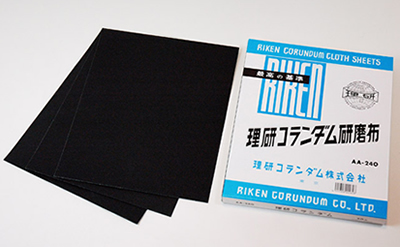

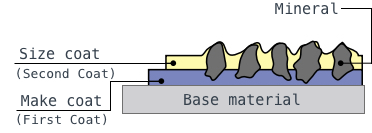

Structure of abrasive cloth paper

- The abrasive cloth paper is an excellent elastic abrasive tool composed of three elements of abrasive, adhesive and base material. Our company develops and provides products that respond to every need by our own technology based on these raw materials.

【Base material】

| Characteristic | |||

|---|---|---|---|

| paper | From flexible flexible thin paper (Awt) mainly used as a sheet, it is selected according to the application from the strength used for ultra wide belt and thick paper (Fwt) with strong back. | ||

| cloth | We use thin fabric (Jwt) which is required flexibility, Xwt as a general base material, dedicated base material with the same longitudinal and lateral strength, and so on. | ||

| the film | Mainly polyester film is used. | ||

【Abrasive material】

| Abrasive material | symbol | Characteristic | |

|---|---|---|---|

| Artificial abrasive | Alumina (Al rundum) | A | It is a red-brown abrasive grain excellent in abrasion resistance, and it is widely used abrasive grain. (Al 2 O 3 aluminum oxide · specific gravity 3.99 · hardness 12) |

| White alumina | WA | A Abrasive grains are higher in alumina purity and less impurities, they are harder and easier to apply, and are white abrasive grains. | |

| Alumina · Zirconia | Z | A grain of black gray which is longer than A abrasive grain. In order to make it small, we constantly grow new cutting edges and obtain a large grinding force for a long time. | |

| Silicon carbide (carborundum) | C | A It is a black abrasive having a flat acicular shape, harder and easier to apply than A abrasive. (SiC silicon carbide · specific gravity 3.12 · hardness 13) | |

| Natural abrasive | diamond | D | Minerals with the highest hardness, popularly made are often used. (Hardness 15) |

| garnet | G | It is a silicate mineral called a garnet. (Hardness 10) | |

| Emery | E | It is a natural A abrasive and is a mineral in which magnetite is finely dispersed in crystal. |

【adhesive】

| adhesive | symbol | Characteristic | |

|---|---|---|---|

| adhesive | Glue (glue) | G | It is not water resistant and adhesive strength is inferior to resin, but it is flexible and provides a soft finished surface. |

| Synthetic resin (resin) | R | It is excellent in water resistance and heat resistance, has strong adhesive strength, it is used for many products, mainly phenol resin, epoxy resin, etc. are used |